How Do 3D Printed Insoles Work for Foot Support?

Foot health is a vital component of overall well-being. With the increase of digital health solutions, one of the most innovative advancements in the field of orthotics is the development of 3D printed insoles. These insoles are rapidly transforming the way we approach foot support, offering an unmatched level of customization, precision, and comfort. But how exactly do they work?

In this blog, we take a closer look at the process behind 3D printed insoles UAE, and how they provide functional foot support with the help of cutting-edge technology.

Step 1: Digital Foot Scanning and Data Collection

The first stage in creating 3D printed insoles begins with a digital foot scan. Unlike old-style methods that rely on physical molds or foam impressions, 3D scanning uses advanced imaging technology to capture a detailed map of the foot’s structure. This includes measurements such as:

- Arch height

- Foot length and width

- Heel position

- Pressure distribution

- Weight-bearing zones

In some clinics, gait analysis is also incorporated to understand how the foot moves during walking. This dynamic data allows specialists to pinpoint any biomechanical abnormalities or misalignments.

The result is an accurate digital footprint that forms the foundation of the custom design.

Step 2: Personalized Insole Design Using CAD Technology

Once the data is captured, it is processed using computer-aided design (CAD) software. This is where customization truly begins. Orthotic experts and biomechanical engineers use the software to:

- Adjust arch support based on foot shape

- Add extra cushioning to high-pressure zones

- Reinforce stability for better posture and balance

- Design corrections for foot alignment issues

Every insole design is unique and built to suit the exact needs of the individual. This ensures that the finished product supports not only the shape of the foot but also the way it moves.

Step 3: 3D Printing the Insole

After finalizing the design, the digital file is sent to a 3D printer. These printers use additive manufacturing methods to build the insole layer by layer using flexible and durable materials. Commonly used materials include medical-grade polymers or thermoplastics that provide:

- Shock absorption

- Flexibility

- Breathability

- Long-term durability

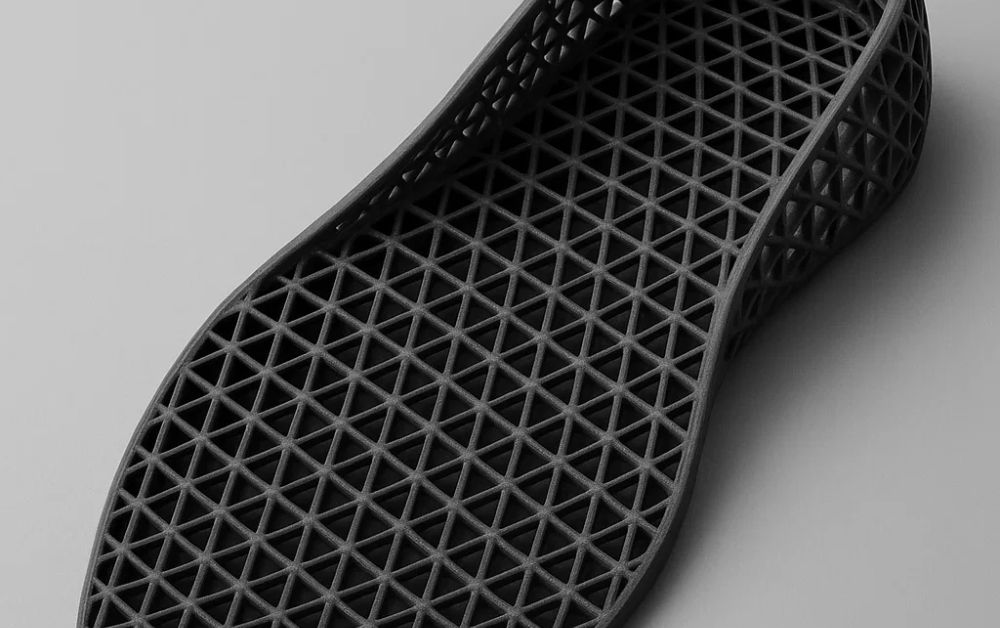

The 3D printing process lets for the precise implementation of complex internal structures, such as honeycomb patterns or targeted reinforcement areas, that would be difficult or impossible to create by hand.

This high level of precision is what sets 3D printed insoles apart from mass-produced alternatives.

Step 4: Quality Control and Final Fitting

Once the insole is printed, it undergoes a quality control process to ensure the dimensions and features match the design specifications. It is then fitted into the user’s footwear for a trial.

During the final fitting, any minor adjustments can be made to optimize comfort and performance. This ensures that the insole integrates seamlessly into the user’s lifestyle—whether for daily walking, sports, or medical rehabilitation.

The Mechanics Behind Foot Support

Now that we’ve covered the process, how exactly do these insoles support the foot?

1. Arch Support

Custom-shaped arches provide stability, reducing strain on ligaments and preventing common problems like flat feet or overpronation.

2. Pressure Redistribution

By analyzing pressure points, 3D printed insoles spread weight more consistently across the foot, relieving pain in high-impact areas like the heel & ball of the foot.

3. Shock Absorption

Specialized materials used in printing help absorb impact forces, protecting joints and minimizing fatigue—especially beneficial for those who stand or walk for long periods.

4. Alignment and Balance

Custom insoles correct foot posture, which positively influences knee, hip, and back alignment. These aids improve balance and reduce the risk of injuries.

Why 3D Printed Insoles Are a Step Ahead

Compared to traditional orthotics, 3D printed insoles offer:

- Greater Accuracy – Designed with millimeter precision based on 3D scan data

- Faster Turnaround – Reduced production time from design to delivery

- Enhanced Comfort – Personalized design ensures a perfect fit

- Advanced Materials – Durable, flexible, and performance-focused components

This innovative solution is particularly valuable in a fast-paced environment like the UAE, where people are increasingly seeking efficient, high-tech healthcare alternatives.

In Conclusion

3D printed insoles UAE represent the next generation of foot support—designed with advanced technology to offer comfort, precision, and personalized care. From digital foot scanning to the final fitting, every step of the process is engineered for optimal performance and support.

If you’re looking for precision-crafted 3D orthotic solutions in the UAE, Ortho Innovations delivers expert care backed by innovation—helping you move with greater comfort, stability, and confidence.